How to design a battery meter(battery tester)?

All kinds of rechargeable batteries are more and more popular in our life. Every mobile electronics devices and electrical equipments have their battery pack. Monitoring battery status is necessary and useful for end user.

How to monitor your battery remain capacity, in other words, how long does my battery keep working normally? There are three algorithms to measure the remain of your battery: "Voltage-Capacity-Curve Lookup", "Current-Accumulating" and "Impedance-Track" method.

Firstly, we discuss "Voltage-Capacity-Curve Lookup" method, hereby we name it as VCL. This algorithms is the simple technology in all three ways. VCL is mornitoring the battery terminal voltage and comparing measured value with build-in fixed voltage-capacity table then give a result of relative remain capacity status. For different chemical battery type, the voltage-capacity curve is different. Further, even for a same battery pack, this curve will be different at higher or lower discharging current. So it is easy to understand why this method only get a gross or rough result. Generally, VCL battery monitor products have 10%~20% relative remain capacity tolerance.

As an example, BG1-XXXX is cited here. You can double click the blue topic words to get more details data of this battery meter or indicator.

|

Feature |

| Designed for 3.6V~48V Li-ion/polymer, or NiMH, or Lead-Acid battery packs. | |

| 5 segments LED indicator, 10% capacity resolution. | |

| Build-in MCU chip, accurate measure battery capacity. | |

| Very slim size: 42x22x5 mm, Fixed easily: self-sticky bottom sheet. | |

| Reverse polarity protection. | |

| BG1-LX (X=1~10) for 1~10series Li-ion/polymer battery-pack | |

| BG1-NXX (XX=3~40) for 3.6V~48V NIMH battery-pack | |

| BG1-AXX (XX=6~48) for 6V~48V lead-acid battery. |

The advantage of this type battery monitor indicator is simple but low cost. If 10%~20% accuracy level can meet your requirements, VCL is the best recommended.

Secondly, we introduce "Current-Accumulating" algorithms ( hereby called CA), this method also named "Coulomb Calculator" or "current integration" . Battery monitor with CA function tracks the remaining capacity of a battery using the Current Accumulator. CA method maintains a net accumulated total of current flowing into and out of the battery. Generally, there are two registers used in these devices , one register for accumulating only charging current, and the other one for accumulating discharging current. Use CA function, a battery monitor not only calculates relative remaining capacity , but also measures absolute capacity (how many Ah or mAh). Comparing with “Voltage-Capacity-Curve Lookup”method, CA algorithm has a higher accuracy level (generally can reach +-5% ), but needs an extra current sensor, and this will lead a more complex wiring installation.

BG2-XXXX battery meter and BG3-XXXX battery monitor from Green Digital Power-Tech are all using this method. Following tables give a brief introduction.

BG2-XXX-X Digital Battery Monitor Meter

|

Feature |

| Designed for 6.4V~48V Li-ion/polymer, LiFePo4, NiMH, NiCd or Lead-Acid battery. | |

| Digital display, monitor voltage / current and capacity easily. | |

| Build-in AVR chip, accurate measuring battery parameters. | |

| Mounting easily: 4 x M3 holes provided. | |

| Input Reverse Polarity protection. | |

| Maximum Current permitted: 5A, 10A, 18A or 28A (selected by last suffix number) | |

| With ON/OFF control connecter in board. | |

| Size: LxWxT=98x35x25mm |

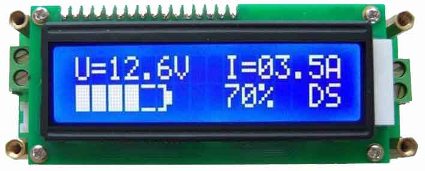

BG-3-XXX Series Battery Gauge indicator (LCD display)

|

Feature |

| Designed for 6V~48V Li-ion/polymer, or NiMH, or Lead-Acid battery packs. | |

| Low cost LCD display panel, easy read all battery parameters | |

| Build-in AVR MCU chip, accurate measure battery voltage, current, capacity fuel gauge. | |

| Standard Industry meter case, easily mounting and fixing. | |

| Reverse polarity protection. | |

| Current Sensor and Temperature Sensor are provided. | |

The third algorithms is called Impedance Track™ (IT) technology. This method is a trade-mark from Texas Instruments (TI )Company. TI claimed that this algorithm has a more precision than Voltage-Capacity-Curve Lookup and Current-Accumulating methods. If you have interesting, you can visit TI’s web site to learn more details about this technology.

There are three ways to display the remaining capacity of a batter pack. The simple way is use a LED array, like BG1-XXXX battery indicator. A better looking and slight expensive way is using a LCD display panel, such as BG2-XXXX battery monitor (or called battery meter). If you device has a SMBus communication port, BMS-Lxx can use this protocol to transfer all battery meters to user’s device.